Precisely the right eggs.

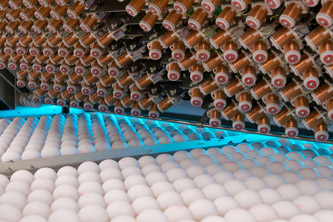

Millions of eggs arrive at our packing station every day. Still, every egg is thoroughly inspected. A piece of automation: accurate monitoring and virtually faultless grading at a dazzling speed.

Advanced technique plays an important role in the grading and packaging process. The specific inspections as well as the repeating logistic actions are mainly performed by robots. Fast, efficient and – mainly this – reliable.

The eggs are

- weighed and graded in sizes XL, L, M and S.

- inspected on cracks and dirtiness of the shell; eggs of lower quality are processed for the industry, eggs with blood spots are removed.

- UV-exposed (not in Laar, Germany), as a result of which germs like Salmonella and Campylobacter are killed.

- packed in small packaging: boxes of 4, 6, 10, 12, 15, 18 or 20 eggs